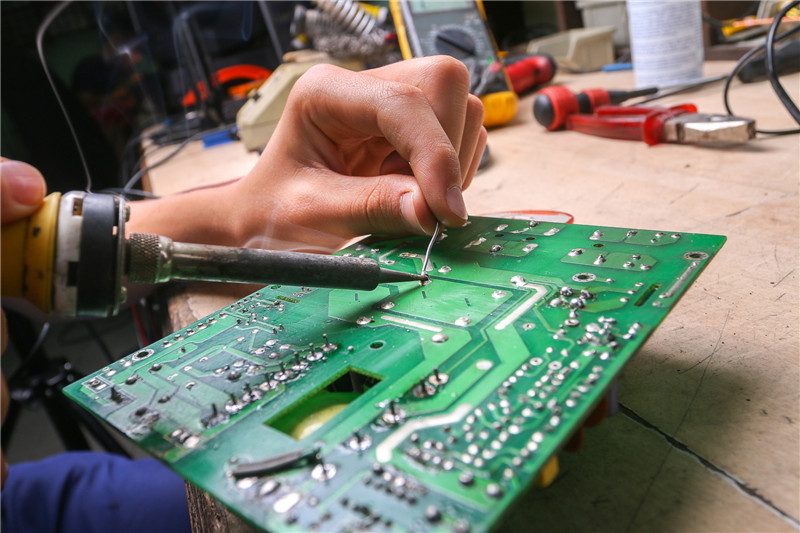

Choose Soldering Iron or a Soldering Station?

Deciding whether to use a soldering iron or a soldering station primarily depends on your specific needs, frequency of use, work environment, and budget. Below is a comprehensive comparison of the two to assist you in making an informed decision.

Similarities and Differences Between Soldering Irons and Soldering Stations

Similarities: A soldering station is essentially an advanced version of a soldering iron, and both tools enable soldering through the application of heat.

Differences:

Heating Principle: A soldering station achieves soldering by heating the solder itself, whereas a soldering iron heats the materials being joined.

Applications: Soldering stations are suited for large-scale soldering projects as they can provide greater heat and power, while soldering irons are better for smaller tasks.

Usage: Soldering stations typically require wires for joining materials, while soldering irons can directly heat the materials.

Temperature Control: Soldering stations often come with digital displays and temperature regulators, allowing for precise control, whereas soldering irons commonly utilize a simple switch for temperature adjustment.

Advantages of Soldering Stations

Efficiency: Thermostatic soldering stations generally have thermal efficiencies around 80%, compared to 50% for traditional soldering irons.

Energy Consumption: Because soldering stations only consume power when heating is necessary, they are generally more energy-efficient.

Temperature Recovery Speed: Soldering stations recover their temperature more quickly, enhancing work efficiency.

Longevity of Consumables: Controlled temperatures lead to less wear, prolonging the life of soldering tips and heating elements.

Safety: The handle voltage of most soldering stations is 24 volts AC, which is considered safe and reduces the risk of electric shock.

Anti-static Features: Many soldering stations come equipped with static electricity elimination functions, which are typically absent in standard soldering irons.

Advantages of Soldering Irons

Portability: Soldering irons are usually lighter, making them ideal for tasks that require mobility or for small soldering jobs.

Cost: Soldering irons are generally more affordable than soldering stations, making them a budget-friendly option.

Recommendations for Selection

Stationary Work Environment: If you regularly conduct soldering tasks on a stable surface, a soldering station offers significant benefits, including superior temperature control, enhanced efficiency, and increased safety.

Mobility Requirements: In situations where you need to move frequently or handle small soldering jobs, a soldering iron may be the better option due to its lightweight design.

In conclusion, both soldering stations and soldering irons have their unique advantages and disadvantages. Your choice should be guided by your specific needs, how often you solder, your work environment, and your budget. We hope this information aids you in selecting the right tool for your projects.

Contact: MDLtool

Phone: +86-16675407880

Tel: +86-16675407880

Email: info@mdltool.com

Add: 3F,Building A2,Baicai Industrial Park,19 Tianbao Road,Baoan,Shenzhen GD ,PRC 518100